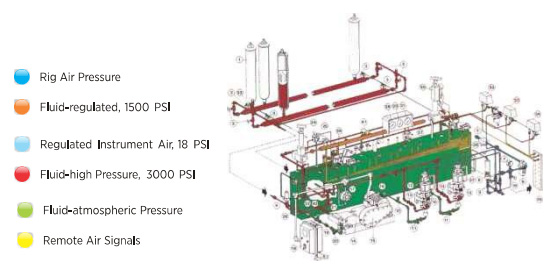

The diverter master panel controls the flowline seals, manifold functions, and diverter packer, which contains and directs wellbore pressure away from the drill floor. The pressure may consist of oil, gas, or water-cut mud, all of which must be diverted to a harmless area.

The diverter master panel has hydraulically-operated functions, air-operated functions, and an air-operated pressure regulator. The hydraulic pressure for the hydraulic functions is provided by the accumulator unit. The air-operated functions and regulators are supplied with rig instrument air.

All diverter functions can be operated from the diverter master panel or remotely from the driller’s control panel and the toolpushrer’s control panel.

Sara Sae Manufacture different type of Diverter:- MSPType, KFDJ Type others

Sara Sae welcomes the opportunity to assist you in the proper selection of standard equipment or custom design to meet your application and certification requirements.

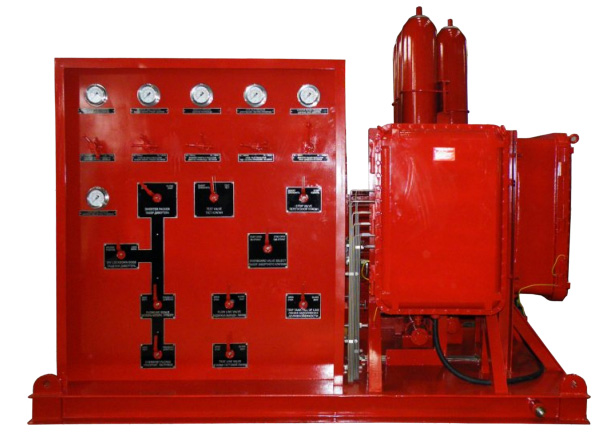

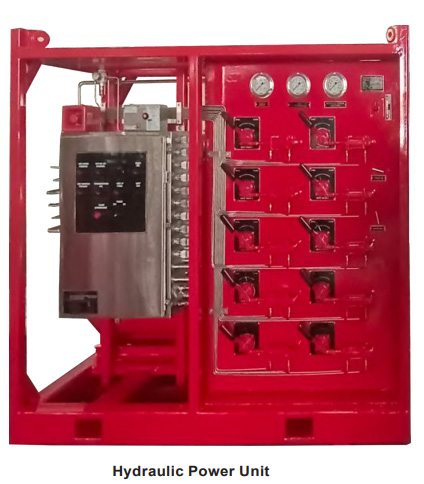

Sara Sae's HCR Panels is a high pressure fitted with directional control valves to provide hydraulic power to operate gate valve. The Hydraulic Power Unit is a skid mounted assembly consisting of fluid storage tank, control valves, regulators and various control components. Sara Sae welcomes the opportunity to assist you in the proper selection of standard equipment or custom design to meet your application and certification requirements.

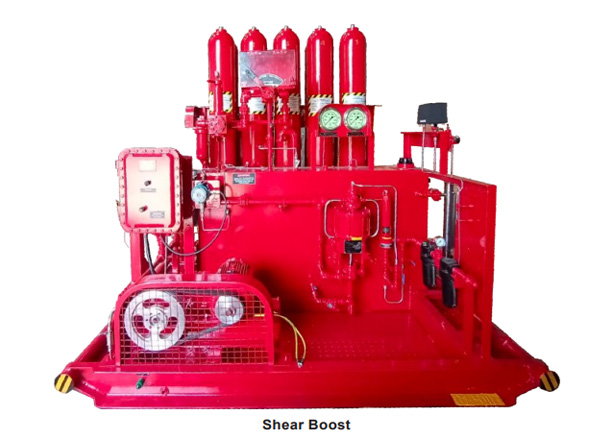

A Shear Boost of Blowout Preventer (BOP) Control System is a high pressure hydraulic power unit fitted with directional control valves to boost the shear pressure to safely control kicks and prevent blowouts during drilling operations. The Shear Boost System is mounted on BOP control unit and consisting of fluid storage tank, hydraulic pumps, control valves, regulators and various control components. The Shear Boost System provides pressurized fluid for the Shear Boost system using the electric driven hydraulic triplex pumps & Air Pumps. Hydraulic pressure from all the pumps is stored in the accumulator bottles mounted on the separate mounted skid. The accumulator bottles have a working pressure of 5,000 psi (352 Kg/Cm Sq.) dedicated to the Shear Boost system.

In addition to the above, Shear Boost valves is also Operated by electric remote control panel. It should be noted the Electric Operated remote panel does not interfere with the manual operation of the control valves at the Shear Boost System. The valves may be remotely operated at the Electric Operated remote control panel or manually at the Shear Boost System. Sara Sae welcomes the opportunity to assist you in the proper selection of standard equipment or custom design to meet your application and certification requirements.

Air Remote Panels control rig air pressure to the hydraulic control manifold to operate the manifold functions. An air interface module is required on the accumulator unit and an air interconnect is required to connect the air remote panel to the interface module. Air remote offered in several standard models to meet usual requirements and are available for any special application upon request. Air-electric panels additionally have explosion proof light stations for each BOP stack function (bypass/ internal override included, when applicable) to indicate open or close status of the hydraulic control manifold valves.

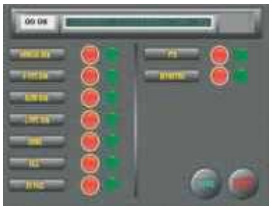

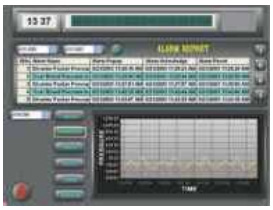

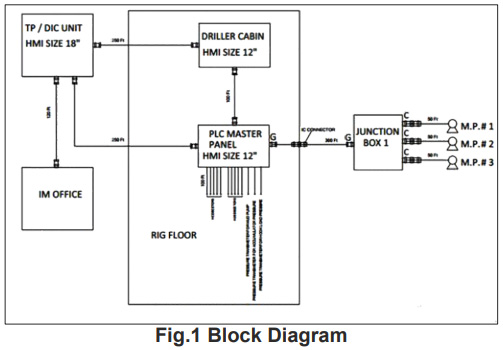

A Workover Rig Monitoring System (RT138) is a comprehensive solution designed to monitor and optimize the operations of workover rigs, which are essential in the oil and gas industry for well intervention and maintenance. This monitoring system leverages advanced technology and data analysis to enhance the safety, efficiency, and productivity of workover rig operations. The RT138 system typically consists of sensors, data acquisition devices, communication infrastructure, and software applications. These components work together to collect real-time data from various aspects of the workover rig, including hydraulic systems, power units, drilling fluid parameters, and overall rig performance. The collected data is transmitted to a centralized control centre or a digital platform (HMI), where it is processed, analysed, and visualized in a user-friendly format. Operators, supervisors, and engineers can access this information to gain valuable insights into the rig's performance, identify any operational issues or anomalies, and make data-driven decisions to optimize rig operations.

The workover rig monitoring system offers several key benefits. Firstly, it improves safety by continuously monitoring critical parameters such as weight on bit, hook load, wellbore pressures, toxic & combustible gas and fluid levels, thereby helping to prevent accidents and equipment failures. It also enables proactive maintenance by detecting early signs of equipment wear or malfunction, allowing for timely repairs and reducing downtime.

Furthermore, the system enhances operational efficiency by providing real-time performance metrics, allowing operators to optimize drilling parameters, adjust equipment settings, and make informed decisions to increase overall productivity. It also facilitates better resource allocation and scheduling by providing visibility into the utilization of rig assets and personnel. Additionally, the workover rig monitoring system enables remote monitoring and control, reducing the need for personnel to be physically present onsite. This capability is particularly valuable in remote or hazardous environments, as it minimizes risks and improves operational flexibility.

Overall, a workover rig monitoring system is a powerful tool that enables real-time monitoring, analysis, and optimization of workover rig operations. By leveraging datadriven insights, it helps improve safety, efficiency, and productivity, leading to cost savings and enhanced performance in the oil and gas industry.

Registered Office

Sara Sae Private Limited INDIA

USA

DUBAI